Understanding the water needs of crops

Australian company Athena IR-Tech has launched a new technology that offers farmers an in-depth understanding of the water needs of their crops.

“Most farmers irrigate based on past cropping experience, but it’s estimated that 40% of irrigation water is wasted each year”, CEO Jay Holata of Athena IR-Tech says.

The company’s technology, named Transp-IR, was developed at the University of Adelaide. It uses infrared sensors and an algorithm to monitor the way water moves through a plant, and how much water is taken up by the roots to use for growth.

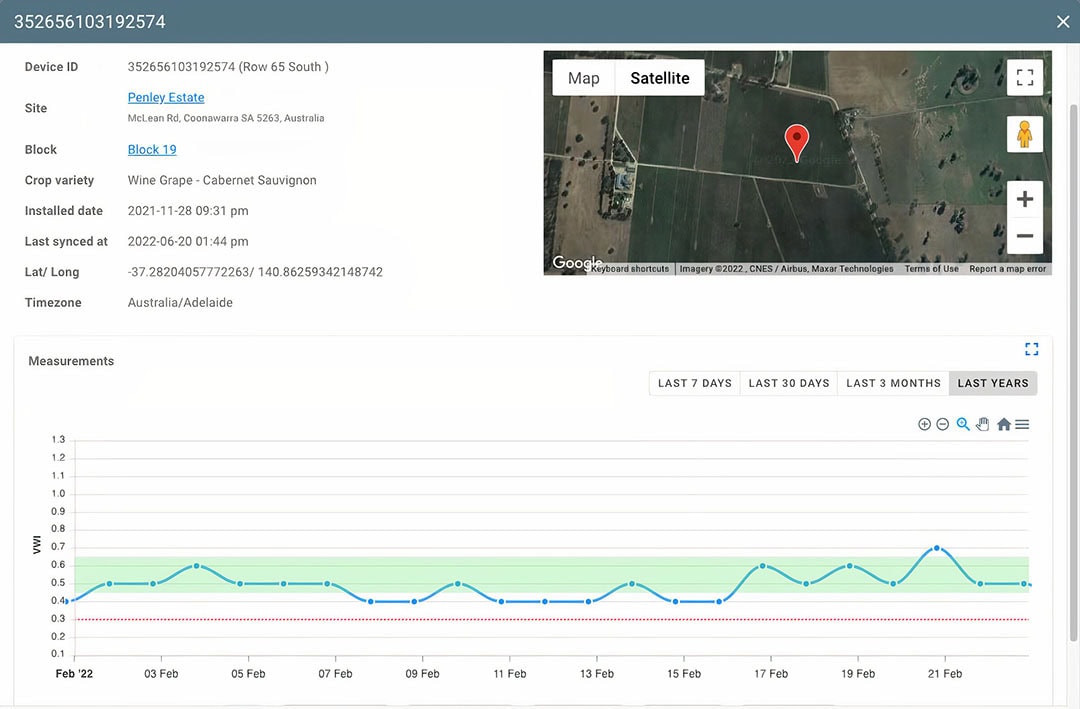

“The system uses an infield device, as well as software”, Mr Holata explains. “The device sits just above the canopy of the crop. It has two infrared sensors that will measure the temperature of the canopy, the ambient temperature, the relative humidity, and the solar radiation. These are the building blocks of understanding how well a plant transpires.”

It’s estimated that 40% of irrigation water is wasted each year

Monitoring how well a plant is transpiring, gives a clear insight in to what extent the plant is making use of the water that is available, and consequently is able to photosynthesize. Transp-IR sends the information every ten minutes via 4G to its algorithm, and creates a crop water index. It also produces an optimal water level that needs to be available for a specific crop to photosynthesise efficiently.

Text continues below picture

Maximising water use efficiency

“You can give every crop a lot of water”, Mr Holata says. “Some crops will just sip it. But other crops will take all the water. Some plants will – instead of putting it into the output you want, such as grapes – put it into building the grapevine, the leaves and branches, that you will have to prune back later.”

The key for growers that use Transp-IR, is to their keep crop water index within the zone of the optimal water level. “That way they maximise their water use efficiency, the level of output based on yield, divided by how much water they gave the crop. How many tons of grapes you get with every megalitre of water.”

Easy to read

Farmers can get access to all available information on a dashboard, that they can view on a phone, pc or tablet. “We made this interface as easy to read as possible”, Mr Holata emphasises. “Growers know the plants have all the water they need, when the water level is in a green zone. If it is below the green zone, the plants need a bit more water to flourish for example. There is also a red line, that indicates when plants go into stress, and might shutdown after a while.”

We first want to establish this new concept with growers

On the dashboard, growers have access to the data, that has been recorded every ten minutes. “They can get a comparison between the leaf temperature and the air temperature for example. That is usually an indication for growers to see if plants have enough water. If the leaf temperature is above the air temperature – and that can easily happen on dry, sunny days – the plants don’t have enough water to transpire. And growers can see the vapour-pressure deficit, an indication of how much water the plants are using.”

Text continues below picture

Text message or email

Mr Holata says he did get feedback from some growers that they don’t necessarily need another dashboard. “They often have too many things to look at already. So, when the crop water index drops below the optimal zone, the system can send a text message or an email to the grower. And it can also send a message when plants are at a critical level.”

At this point, the system does not activate irrigation. “We first want to establish this new concept with growers, and then will be looking at adding new capabilities”, Mr Holata says. “Providing a forward-looking crop water index for the next few days and turning on irrigation controllers are part of our roadmap.”

The technology was initially available for vineyards with the grape varieties Cabernet Sauvignon and Shiraz. In the past growing season, the Adelaide-based company has added ten more grape varieties, as well as Imperial mandarins, non-pareil almonds, navel oranges, and Valencia oranges. All will be available at the start of the 2023-2024 growing season.

Text continues below picture

Flavour intensity

According to research of Wine Australia – led by Dr Vinay Pagay from the University of Adelaide – using data-driven irrigation schedules such as Transp-IR, has been shown to increase water use efficiency three-to-six-fold in Cabernet crops, and double in Shiraz, compared to conventional methods. The recently completed project found data-driven irrigated vines consistently outperformed conventionally irrigated vines.

The advantages of the system depend on the specific crops or cultivars, Mr Holata points out. “With almonds for example, the main advantage will be to use less water to achieve the same yield outcome. When it comes to wine grapes, we can give growers the ability to adjust their optimal zone for different phenological stages of the crop, to help them to improve a certain characteristic, such as the flavour intensity or the colour of the grapes.”

Currently, 41 growers are using Transp-IR across Australia and New Zealand. Nex year, Athena IR-Tech plans to introduce its technology to grape, almond and citrus growers in the Central Valley of California.

The company is now seeking investment and commercial partners to fund research & development for new crops, develop the next generation of hardware and software and expand Transp-IR throughout wine and horticulture regions in Australia, New Zealand, the United States, and eventually to Europe, South America, and South Africa.

Join 17,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the agricultural sector, two times a week.