Dedalo rover to autonomise very narrow orchards

FieldRobotics, a young spin-off company of the University of Bologna, is developing robotic field rover Dedalo. Dedalo is patented on four aspects and able to carry payloads up to 1,000 kg.

Only just recently spun-off from the University of Bologna in Italy, FieldRobotics was founded because of the market potential it sees for its robotic field rover concept named Dedalo.

Lorenzo Marconi, a professor of automatic control at the Department of Electrical and Information Engineering of the university co-founded the startup in February 2022. In an interview with Future Farming, he explains that the technology was developed over the past five to six years. “Before I was in charge of many European projects – especially on drones – but I expect the difference in agriculture will be done on the ground, not in the air because of the various big challenges farmers are facing. Our idea is to develop a very light-weight and compact autonomous rover that is modular in terms of the implements it can carry. We trialled both internal combustion engines and electrical drive lines but will focus on the latter from now on.”

Text continues below video

Strong local demand for automated solutions

Marconi explains that local farmers express a strong demand for automated solutions to help them in the field. “The demand is primarily driven by Italian farmers growing pears in orchards. Not only for autonomous crop care, but also for robotic harvesting. We hope to be able to start a project on robotic pear harvesting supported by the local authorities.”

Two years ago, Marconi’s team at the university started to ‘harvest’ data in orchards using the cameras of the navigation system. “With that, we started building digital twins of orchards. Our navigation system uses cameras and LiDAR and is able to navigate in very narrow (2 m interrow) orchards even if GNSS reception is poor because of anti-hail nets. It resulted in us getting a patent on the navigation technology. As an operator, you tell the robot where to start, where the first row is and how many rows there are.”

Driving from one row to another is done based on visual camera images, this manoeuvre is not pre-programmed but relies on end of row detection and on a 3D reconstruction of the environment. Driving backward autonomously is also possible depending on the type of implement attached.

Text continues below image

Four patents in total

“But that’s not the only patent we got”, Marconi continues. “We also have three patents on mechanical solutions: on the weight distribution system, the adjustable track system and on the way we carry implements in the front to maintain an optimal weight distribution. Dedalo, weighing less than 900 kg itself, can carry payloads of up to 1,000 kg. Such as bins with harvested pears or apples.”

Second generation of Dedalo

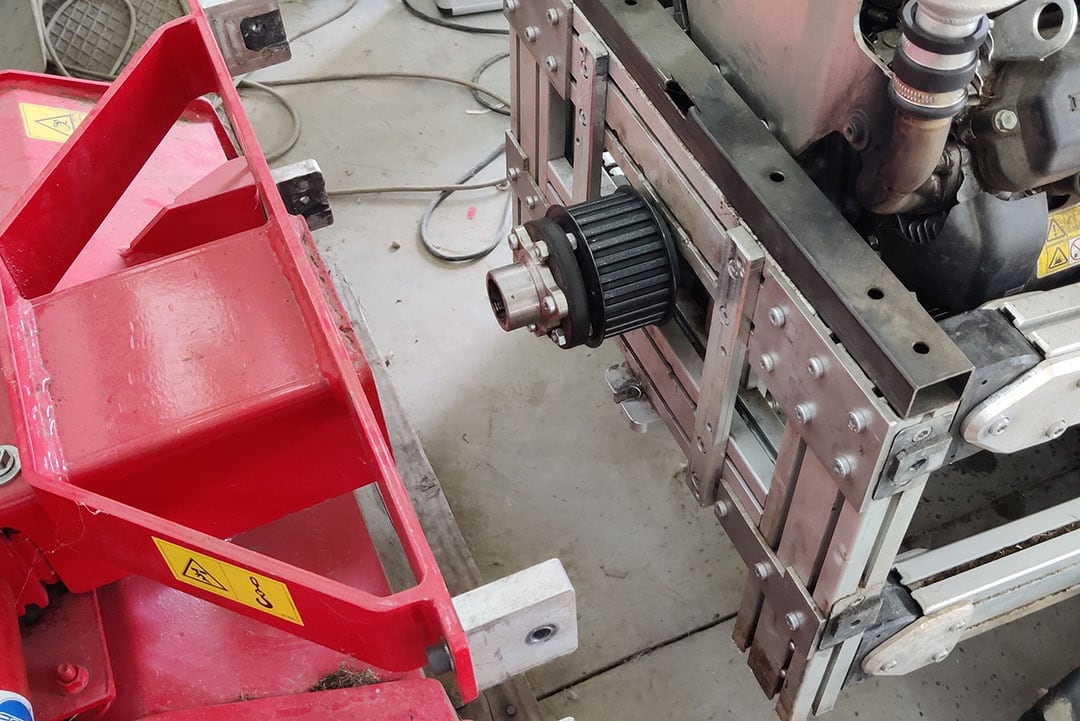

FieldRobotics is currently working on the second generation of Dedalo that can not only operate a sprayer and a mulcher and will also be more robust and lower. The driveline is full electric and it is equipped with two or four modules of 6 kWh battery packages. As for the implement, two power systems are possible: an electric or an endothermic one. The endothermic solution is based a two-cylinder Honda petrol engine with 25 hp.

Dedalo’s autonomy in flat terrain is assumed to be 9 hours with a 6-kwh battery and no implements attached. On a 20% slope, the autonomy is 5 hours under the same conditions. Both assumptions are made based on standard usage and thus not 100% of the time in motion. The rover can handle slopes up to 30% and can achieve a maximum speed of 6 km/h.

Text continues below image

Starting price around € 30,000

While FieldRobotics is developing the technology, it cooperates with an industrial partner for production and servicing of the robots. Commercial introduction is anticipated by the end of this year and Lorenzo Marconi estimates the starting price for the basic entry level platform with 12 kW battery capacity should be around € 30,000. “The margin needs to come from selling the matching implements”, he says.

As the track width is adjustable, Dedalo can also be adapted to working in orchards and vineyards with other row distances and in other crops like tobacco and melons, but also in greenhouses. A docking station for charging the batteries automatically is currently under development. Other current developments include an automatic refill option for the sprayer tank and a system for automated changing of implements.

Join 17,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the agricultural sector, two times a week.