Dutch develop “WeedAway” field robot for eradication of dock leaf

Up north in the Netherlands, four specialists with different backgrounds are developing an autonomous vehicle to detect and treat dock leaf in pastures. Other arable applications are also planned.

The four united in the startup called WeedAway to develop their field robot with the same name. The 20 kgs lightweight vehicle is able to treat dock leaf plants, initially by spot spraying an herbicide, after the plants were first mapped by a drone and indicated on an application map. The robot then drives to every single location identified to apply an herbicide dosage.

Targeted next are row crops like valerian and onions and later on strip cropping and intercropping as well. The company also experiences serious interest from golf courses and sports accommodations. The initial treatment might focus on herbicides, electrocution of weeds is also being researched. A third means of interest is laser technology.

Text continues below video

WeedAway to run for 24 hours

The current look of the WeedAway robot resembles the final look by far. It is purely built to enable the developers to test their methods of navigating to the indicated locations of dock leaf, to determine whether that plant really is a dock leaf and then apply an herbicide.

The parts nonetheless give a clear indication of what their plans are. The energy for propulsion, steering and herbicide application is generated by a single high-capacity solar panel that also determined the dimensions of the robot. Its four 48-volt batteries are used for energy storage and should enable it to work for 24 hours continuously.

Text continues below image

The current rear wheels are small, narrow and suspended and are each driven by an electrical wheel motor. The two front wheels, currently from a wheel barrow, are used to steer the vehicle. Eventually, all four wheels will be bigger in size and steerable to manoeuvre efficiently in row crops as well.

The front panel is fitted to a safety sensor that stops the robot as soon as something or someone hits the panel. Until then, the surroundings are observed by a suit of ultrasonic sensors at each corner of the vehicle.

Text continues below image

Verifying the location of weeds

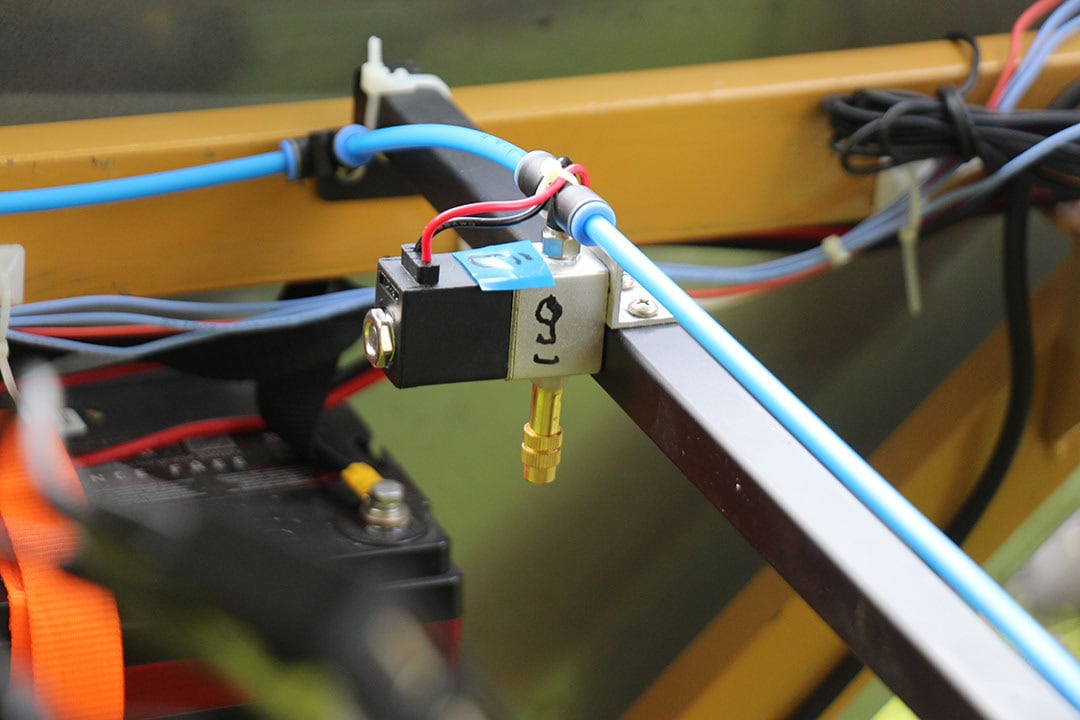

Under the ‘hood’, there’s a compact RGB camera that photographs each supposed weed while standing still to verify whether that plant really is the type of weed targeted. Dock leaf in a pasture in this case. If it is dock leaf, the robot applies an herbicide dosage with one or more of the currently nine nozzles.

To the left and right of the central RGB camera, there’s two more similar cameras intended to get additional reassurance of the weed(s) detected in more challenging crops like onions in future. Eventually, the nine nozzles are to be replaced by a single nozzle that can move freely to adjust to the targeted weed(s).

Text continues below image

Target price: €30,000

In agriculture, WeedAway expects interest in their concept from contractors mainly. The starting price is targeted at € 30,000. The current setup requires an application map with the dock leaf plants indicated on it by means of a drone flight.

ABdrone, another company of one of the four founders, can provide such flights and application maps in the Netherlands for € 50/ha with a minimum of 10 ha. Each additional hectare costs € 35. It requires an orthomosaic image of the field(s) in question with a 7 mm pixel size and accurate RTK-gps coordinates.

For 2022, WeedAway has managed to find 9 of the 10 desired paying Dutch customers whose investments will help finance finalisation of the commercial version of the robot as well as future developments including weed electrocution and lasering.

Join 17,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the agricultural sector, two times a week.